ABOUT US

QUALITY CHANGES THE WORLD

About HOSON Water Technologies | HOSON Water Technologies

A Global Leader in Membrane Water Purification Solutions

With over 15 years of experience in membrane separation technology and water treatment, HOSON Technology, leveraging ultrafiltration membranes as its core technology, has built a comprehensive service system encompassing seawater desalination, industrial water treatment, municipal water supply, smart water services, commercial water purification, and household water purification. As of 2025, over 7,000 ultrafiltration membrane water purification stations have been deployed in 13 countries worldwide, serving over 30 million people. Its core products and solutions have received international certifications, including those from Japan Waterworks and the US National Water Safety Administration (NSF), making it a key force in promoting the sustainable use of water resources.

Our Mission and Positioning

Core Mission

With our mission to “protect the purity of every drop of water and empower healthy lives for billions of families,” we focus on addressing complex water quality treatment and efficient water supply needs, ensuring access to high-quality purified water in cities, rural areas, and industrial settings, and providing safe, environmentally friendly, and economical water security for human life and industrial development.

Core Technology: Leading Industry Innovation with Ultrafiltration Membranes

The PVC alloy capillary ultrafiltration membranes and anti-fouling PVDF ultrafiltration membranes used in our products are the core support for third-generation water treatment processes. Key technical indicators and advantages are as follows:

1. Ultimate filtration precision: Average pore size of 0.01μm (only one ten-thousandth the diameter of a human hair), uniform pore size distribution, and a microbial removal rate of 99.9999%. It effectively intercepts bacteria, viruses, and colloids while preserving natural minerals in the water.

2. Strong environmental adaptability: Acid and alkaline resistance range of pH 1-14, temperature tolerance of 5-45°C, and outstanding pollution resistance make it suitable for complex water conditions such as high turbidity, high salinity, and high COD (for example, the Hubei Macheng project maintained stable water production despite raw water turbidity of 50-80 NTU).

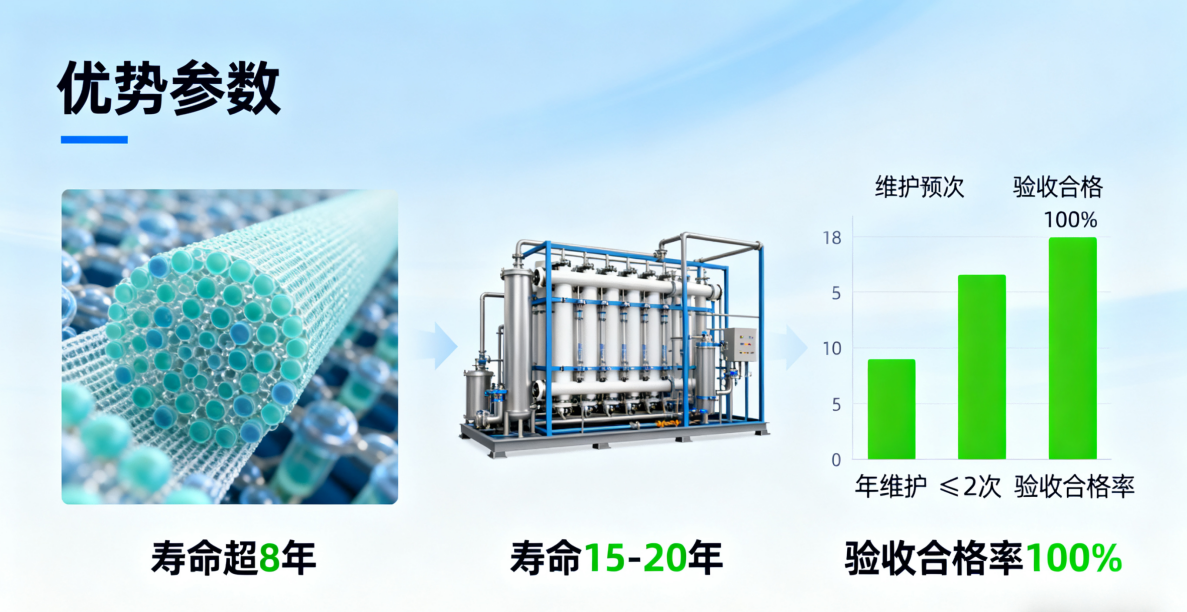

3. Low-energy, long-lasting operation: Low-pressure, high-throughput design (operating pressure 0.1-0.3MPa), with energy consumption per unit of water as low as 0.08kWh/m³. Industrial-grade PVDF membranes have a lifespan of over 8 years, while municipal-grade PVC alloy membranes have a lifespan of 5 years. Annual maintenance frequency is ≤2 (the membrane modules at the Murrurundi Water Plant in Australia have been in continuous operation for 8 years). Flux attenuation rate <15% per year);

4. Authoritative Technical Certifications: We hold over 100 domestic and international invention patents. Our products are certified by Japan Waterworks, the US NSF, and the California Department of Public Health, earning global recognition for our technological strength.

Full-Scenario Product and Solution System

Leveraging our core membrane technology, we provide customized water purification services for diverse sectors, covering all water use scenarios from industrial production to domestic use:

1. Seawater Desalination Equipment

• Product Matrix: FSHB Series (daily output 0.5-320 tons), including conventional models (FSHB 0.5/1.5/10), containerized models (FSHB 50/100/320), and project-customized models (such as the CNOOC Xijiang/Liuhua/Wushi models);

• Core Advantages: Salt rejection >99.2%, rust-resistant and corrosion-resistant 316L stainless steel housing (lifespan 15-20 years), compatible with 220V/380V/440V voltages, and water produced complies with the “Sanitary Standard for Drinking Water” (GB 5749-2006);

• Typical Applications: Island water supply (Riau Islands project in Indonesia), marine water supply (compliant with Classification Society CS standards), and emergency water supply (Cape Town drought relief project in South Africa).

2. Industrial Water Treatment Solutions

• Core Products: Submerged PVDF/PM composite membrane curtain (LJ1), submerged equipment (LGJ1/LGJ2), pressure membranes (LH/LW), reverse osmosis membrane elements (LRLP low-pressure, LRSW seawater desalination series);

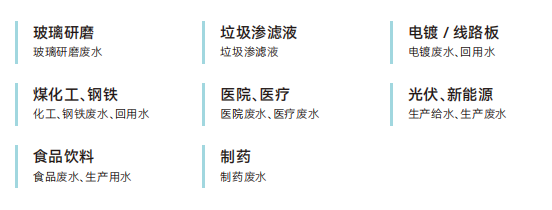

• Service Areas: Providing full-process solutions for process water purification, wastewater treatment, and wastewater reuse in eight major industries, including glass grinding, electronics, coal chemical, steel, photovoltaics, pharmaceuticals, and food;

• Benchmark Case Studies: Changsha Glass Grinding Wastewater Treatment Project, Zhuhai Electronics Factory Circuit Board Wastewater Reuse Project, Venice Industrial Park Wastewater Treatment Project in Italy, and Tarragona Industrial Park Wastewater Treatment Project in Spain.

3. Municipal Water Treatment Solutions

• Technology Positioning: Third-generation tap water treatment process (ultrafiltration membrane as the core), with an industry-leading application scale exceeding 4.5 million tons/day by 2023;

• Core Products: Pressure membranes, submerged PVDF composite membrane equipment, and nanofiltration membrane elements;

• Typical Applications: New water plant construction (Haikou Jiangdong New District High-Quality Drinking Water Plant, 200,000 tons/day), upgrading and reconstruction of existing water plants (Beijing No. 9 Water Plant, 700,000 tons/day), and municipal wastewater treatment (Dongguan Dalang Songshan Lake Southern Wastewater Treatment Plant);

• Water Quality Assurance: Stable effluent turbidity <0.1 NTU, in compliance with the “National Standard for Drinking Water Quality” (GB 5749-2022), reducing flocculant and disinfectant usage by 30%, and minimizing the risk of disinfection by-products.

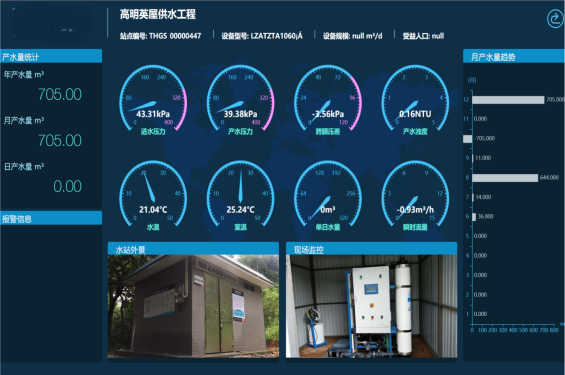

4. Smart Water Solution

• Technical Features: Core to “high-performance ultrafiltration membranes + standardized equipment + IoT management + professional operation and maintenance,” awarded the “Advanced Practical Technology Promotion Certificate” by the Ministry of Water Resources;

• Core Value: Adaptable to the dispersed water sources and uneven population distribution of villages and towns, with strong shock load resistance (maintaining stable water production even after heavy rains with fluctuating raw water turbidity), support for remote wireless monitoring, and a 50% reduction in operation and maintenance costs;

• Benchmark Case Studies: Guangdong Yunfu Luoding Entire Natural Village Water Supply Project (19 project sites); Zhaoqing Fengkai Centralized Water Supply Project for 37 Natural Villages; and Xinjiang Urumqi Hongyanchi Water Plant Village-Level Water Supply Points (100,000 tons/day).

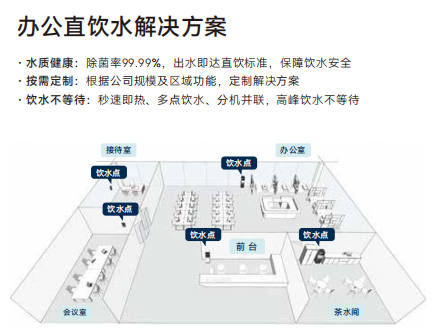

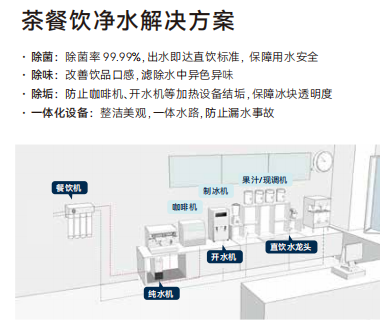

5. Commercial Water Purification Solutions for All Areas

• Application Scenarios: Business offices, restaurants, healthcare facilities, campuses, airports, high-speed rail stations, and other public spaces;

• Product Portfolio: Commercial water purifiers (D510/D500/D300 series), hot and warm water dispensers (DF500/DF300 series), public outdoor drinking fountains, walk-in/bar water heaters, ultrafiltration/kitchen water purifiers, and commercial water purifiers;

• Core Advantages: 99.99% sterilization rate, 80% energy savings through heat exchange technology, intelligent water quality display and cartridge replacement reminder, suitable for groups of 30-200 people.

6. Home Water Purification Solutions

• Core Products: Centralized ultrafiltration water purifiers (such as the LU3B1-82C, 0.01μm filtration accuracy, stainless steel body with a 6-year warranty), pre-filters, ultrafiltration companions, water softeners, and instant hot water dispensers;

• Service Concept: Covering the entire “eating and bathing” experience, pure physical filtration eliminates wastewater, requires no electrical connections, preserves natural minerals in the water, and provides “whole-home mineral drinking water coverage.”

Global Benchmark Case Studies: Proven Strength in Practice

Key Domestic Projects

• Municipal Water Supply: Beijing No. 9 Water Plant (700,000 tons/day, a model for upgrading an existing plant);

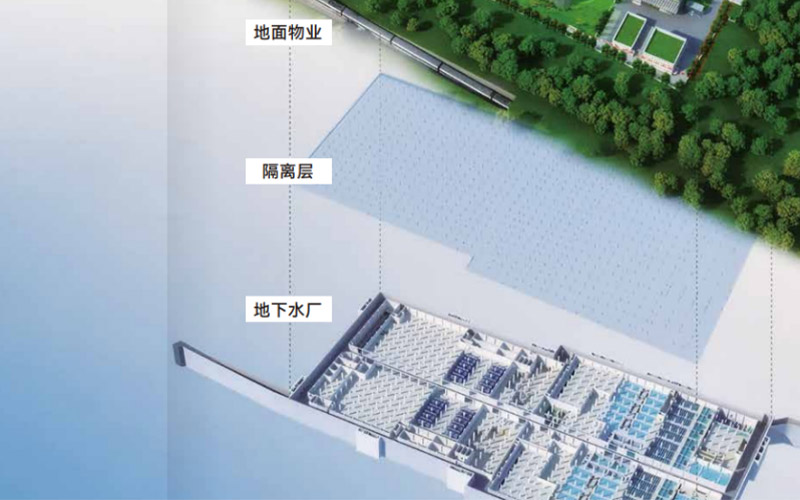

• Haikou Jiangdong New District High-Quality Water Plant (Asia’s first sunken water plant, 200,000 tons/day)

• Langfang Surface Water Plant (300,000 tons/day);

•Industrial treatment: Changsha glass grinding wastewater project (high suspended solids treatment)

• Zhuhai Electronics Factory Circuit Board Wastewater Reuse Project (High-salt Wastewater Resource Reuse);

•Rural drinking water: water supply to 19 natural villages in Luoding, Yunfu, Guangdong (decentralized smart water supply),

• Centralized water supply for 37 villages in Fengkai, Zhaoqing (covering 28,000 villagers)

Classic Overseas Projects

• Southeast Asia: Kampot Water Plant, Cambodia (7,000 tons/day, Cambodia’s largest ultrafiltration water plant);

• Cambodia Sveleon Water Plant (Cambodia’s first UF technology project)

• Indonesia Dumai Desalination Project

• Europe:

• Venice Industrial Park Wastewater Project, Italy

•The largest industrial wastewater MBR project in Europe has been successfully operated for 12 years.

• Wastewater treatment project in Tarragona Industrial Park, Spain

• Oceania: Murrurundi Water Plant, Australia (2,500 tons/day, stable operation for 8 consecutive years);

• Africa: A desalination plant in Mauritania, Africa (2,400 tons/day, stable output of domestic water for 2 consecutive years);

• Liberian Peacekeeping Force Emergency Water Supply Station (4-hour rapid deployment, 100% water quality compliance).

Our Core Advantages

1. Technological Leadership: Patented membranes + comprehensive solutions. Our ultrafiltration membranes are used in municipal applications at a scale exceeding 4.5 million tons/day, leading the market share of similar products.

2. Stable and reliable: The service life of industrial membranes exceeds 8 years, the service life of seawater desalination equipment is 15-20 years, the annual maintenance frequency is ≤ 2 times, and the project acceptance rate is 100%;

3. Energy saving and environmental protection: Reduce chemical usage by 30%, and reduce unit water energy consumption by 18% below the industry average. All projects comply with the “Green Factory Evaluation Standards”;

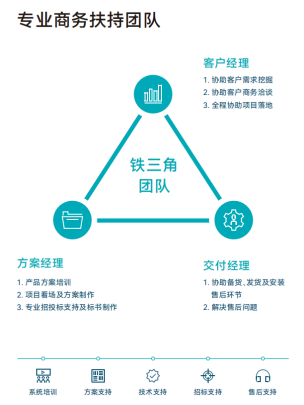

4. Service guarantee: Rapid response from nationwide outlets, 24/7 service hotline, 48-hour on-site maintenance, and a comprehensive “account manager + solution manager + delivery manager” team to fully support project implementation.

Future Vision: We will continue to focus on membrane material upgrades and digital transformation, driving breakthroughs in ultrafiltration membrane technology toward lower energy consumption, higher precision, and a wider range of applications. We plan to add 20 new demonstration projects along the Belt and Road Initiative by 2030, establishing Hesheng as a global leader in sustainable water solutions.

A HISTORY OF PROGRESS

TRUSTED ALL OVER THE WORLD

-

146Invention Patents

-

26Directly Affiliated Branches

-

60Product Distribution Countries

-

Hoson Technology Co., Ltd.

Hoson Technology Co., Ltd.

-

Germany

-

Spain

-

Italy

-

Kobiria

-

Nigeria

-

Myanmar

-

Thailand

-

Cambodia

-

Laos

-

Australia

-

Indonesia

-

Tang Family

-

Philippines

-

Japan

-

Türkiye

-

Russia

FACTORY FOCUS