Hoson Global Smart Membrane Water Supply Solution: Smart Water Service Details and Services

Core technology system

PVC alloy capillary ultrafiltration membrane

1.1 Technology Positioning

As the core carrier of Hoson Smart Water, this membrane material has overcome the technical difficulties of “industrial production of high-quality ultrafiltration membranes using PVC materials”, effectively solving the industry pain points of traditional PVC membranes being prone to brittle cracking and poor pollution resistance, and providing a stable water purification foundation for the smart water system.

1.2 Core technical parameters

Its nominal pore size is 0.01μm, and the transmembrane pressure is controlled in the range of 0.04-0.08MPa; the pH tolerance range is as wide as 2-13, which can adapt to water sources with different acidity and alkalinity properties; the water temperature adaptability range is 5-40℃, covering the temperature conditions of most natural water sources; the water turbidity is ≤0.1NTU, the bacterial filtration rate is ≥99.99%, and the pollution index (SDI15) is <1, ensuring that the water quality meets safety standards.

Water turbidity: less than 0.1NTU, the lowest can reach 0.01NTU

Microbial removal rate:

| target | Removal rate (log) |

| Cryptosporidium | >6 |

| Giardia lamblia | >6 |

| Escherichia coli | >6 |

| Virus | >4 |

| Test results from the National Science Foundation (NSF) Water Quality Center | |

1.3 Core technology advantages

The structural design utilizes a capillary layout, enabling cross-flow filtration. Contaminants on the membrane surface are easily removed through backwashing, and the chemical cleaning cycle is up to 180 days per cycle. In terms of durability, the membrane filaments have a tensile strength of 157N per strand, and with normal maintenance, a service life of over 10 years is expected. The membrane also offers excellent energy efficiency, utilizing its low-pressure operating characteristics to reduce energy consumption by over 30% compared to traditional ultrafiltration membranes.

2: PVDF ultrafiltration membrane

2.1 Technology Positioning

As an ultrafiltration membrane designed specifically for extreme working conditions, it is primarily suitable for demanding applications such as high pollution, strong chemical corrosion, and high temperatures. Together with the PVC alloy capillary ultrafiltration membrane, it forms a complementary product system encompassing “general scenarios + special scenarios” to meet diverse water treatment needs.

2.2 Core Technical Parameters

The nominal pore size is 0.02μm, and the transmembrane pressure is 0.06-0.10MPa. The pH tolerance range extends to 1-14, allowing it to withstand both strongly acidic (e.g., 5% hydrochloric acid) and strongly alkaline (e.g., 10% sodium hydroxide) water. The water temperature range is 5-50°C, allowing it to treat high-temperature industrial wastewater. It can withstand long-term residual chlorine concentrations of ≤5000ppm, eliminating the need for additional dechlorination steps. The membrane has a tensile strength of 200N per strand, and the produced water turbidity is ≤0.2NTU, meeting industrial water standards.

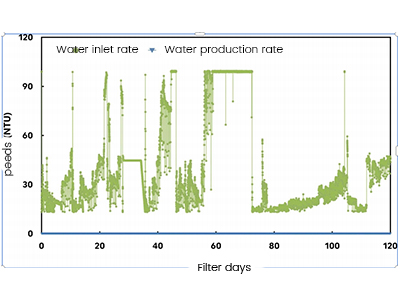

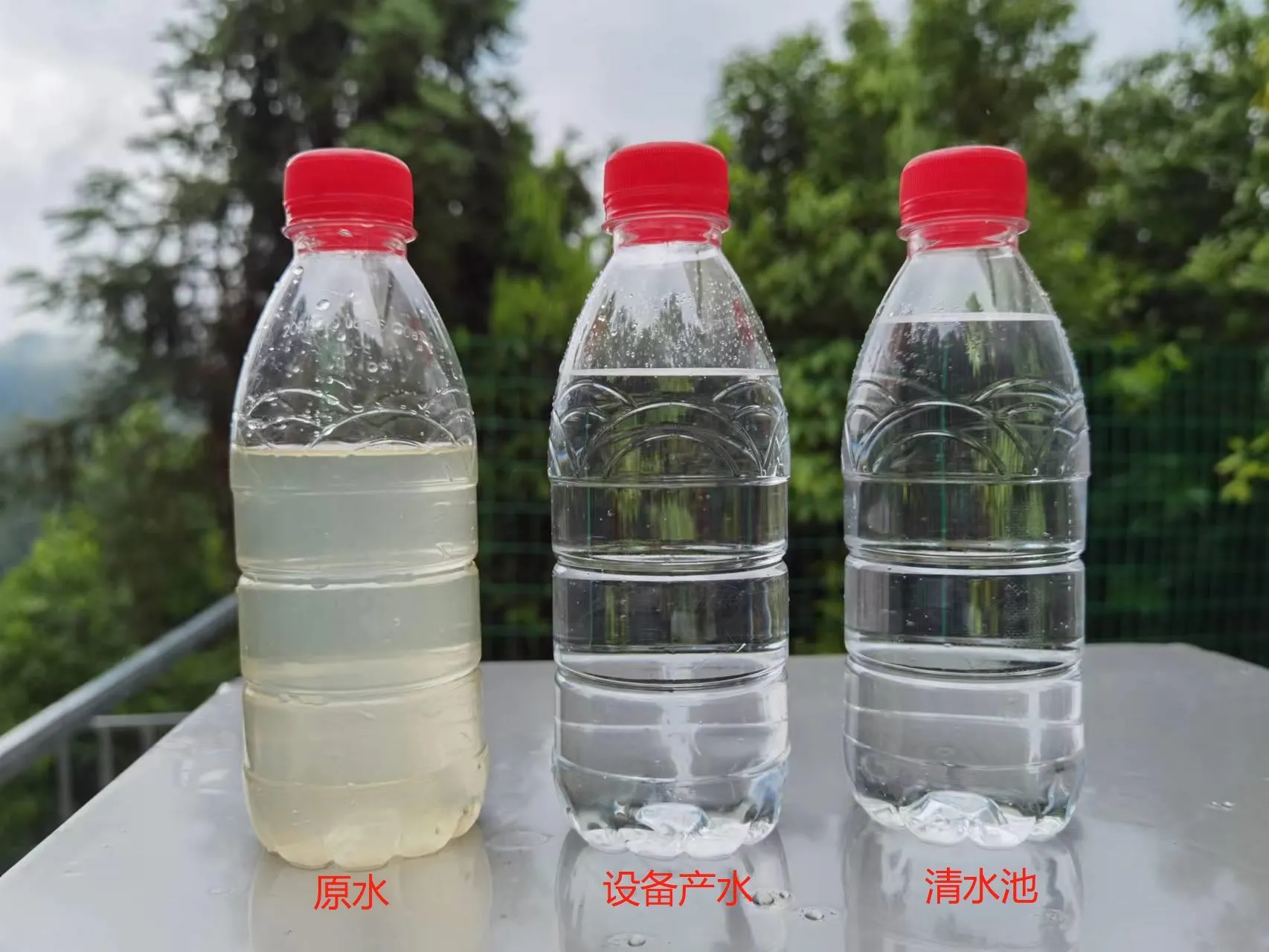

On-site filtering effect demonstration:

2.3 Core Technology Advantages

The structure adopts a three-layer composite support design of “reinforced fiber + PVDF base membrane + anti-pollution coating”. Even under the high-pressure backwash condition of 0.15MPa, the wire breakage rate is still less than 0.1%; the anti-pollution performance is outstanding, and the membrane surface is covered with a nano-scale anti-pollution coating (contact angle ≤ 60°), which reduces the adsorption of organic matter and colloids, and the chemical cleaning cycle is extended to 270 days/time; it has strong weather resistance, does not crack at low temperatures of -20℃, and does not soften at high temperatures of 50℃, and can stably cope with extreme temperature and chemical corrosion scenarios.

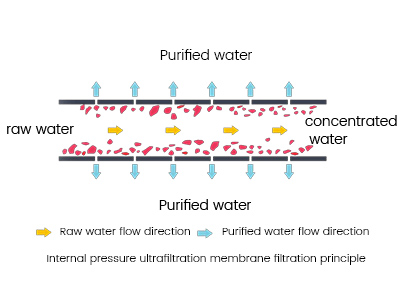

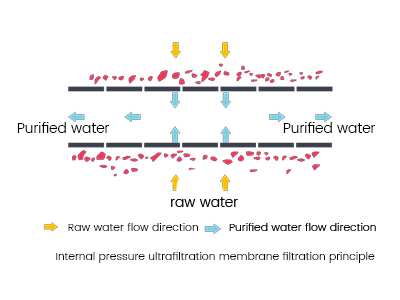

3. Filtration principle diagram

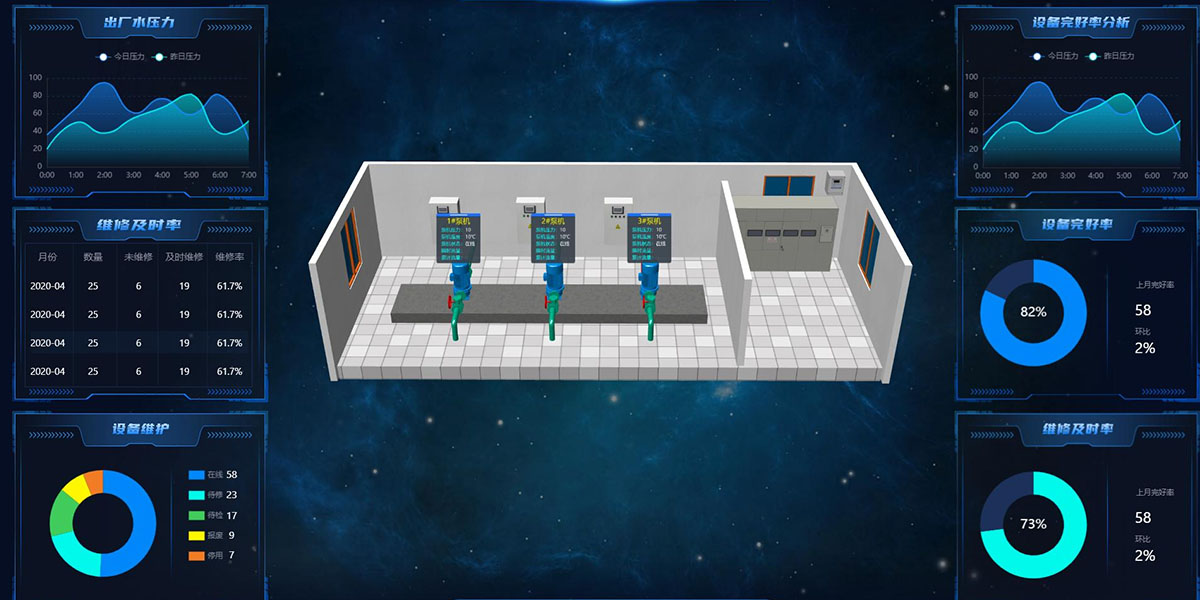

4. Intelligent upgrade architecture

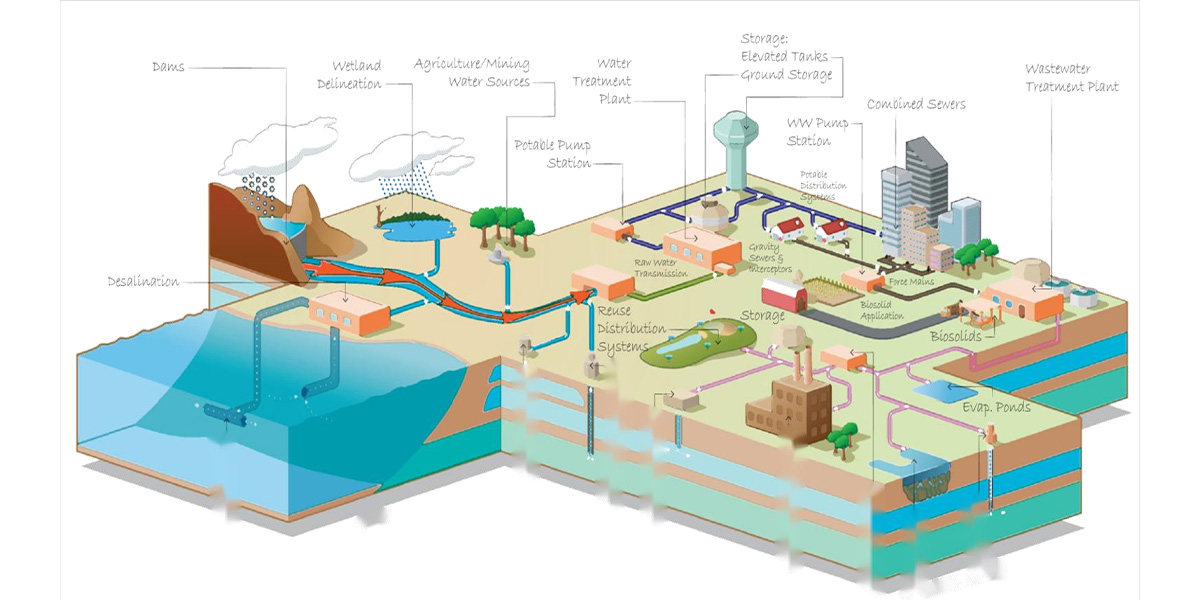

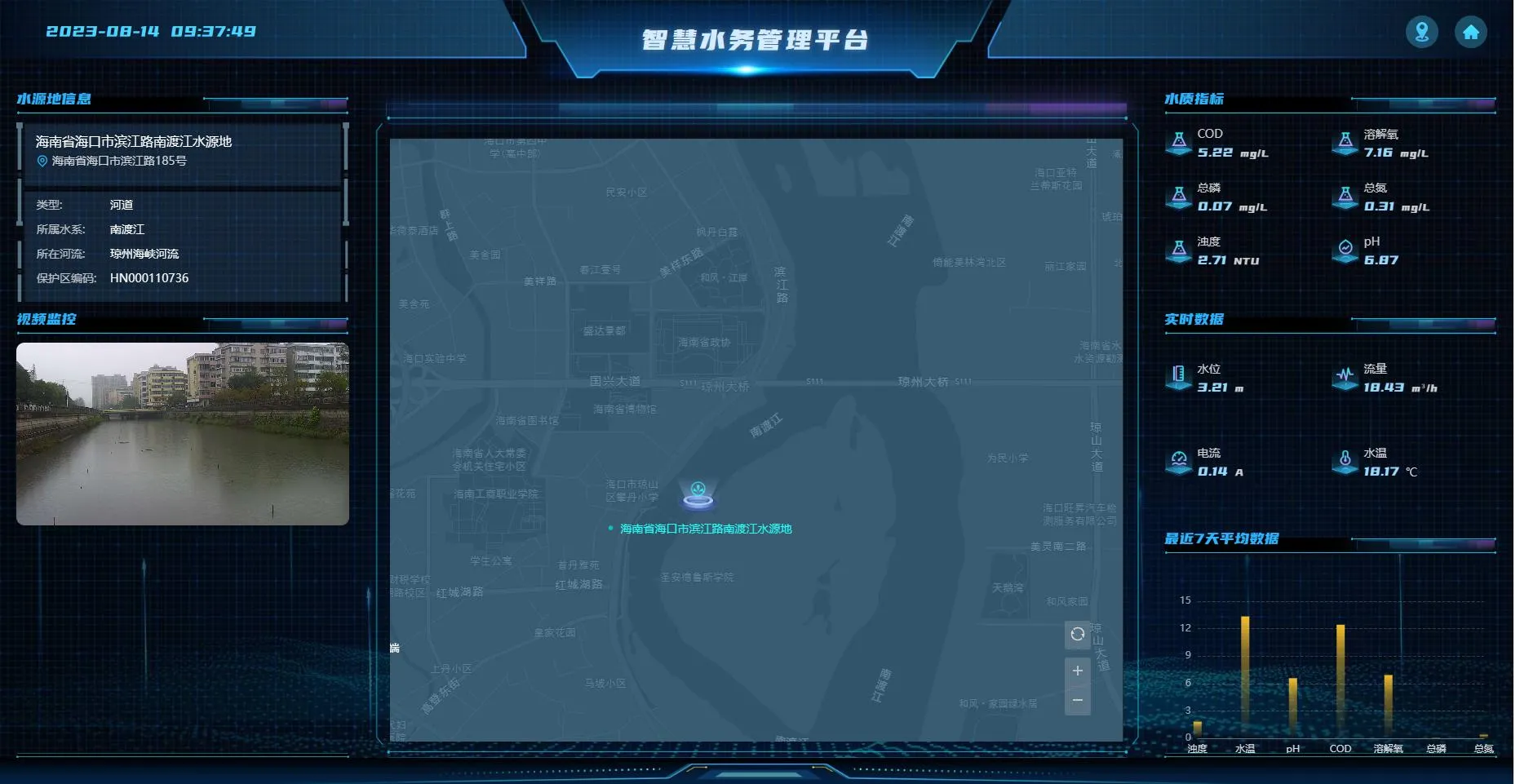

Adopting the three-tier architecture of “membrane technology + Internet of Things + big data”

covering the entire process of “water source – water plant – pump station – pipe network – user end”, making the entire water supply process monitorable, dispatchable and traceable

Perception layer

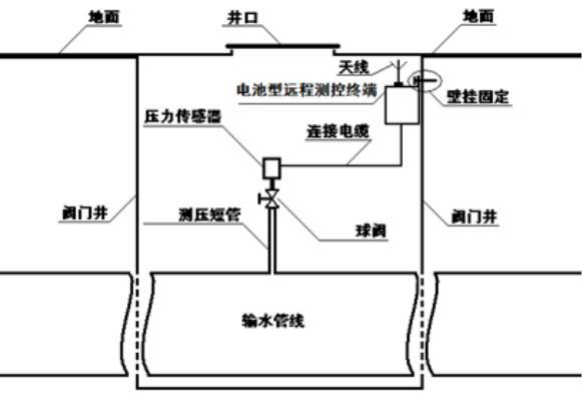

Deploy water quality sensors, pressure transmitters, smart water meters and other equipment to achieve real-time collection of water temperature, turbidity, water pressure, flow and other parameters through NB-IoT/LoRa low-power networks

Platform layer

Build a water service big data platform to integrate equipment operation, pipe network status and user water consumption data, and support multi-dimensional analysis and intelligent decision-making

Application layer

Develop WEB management platform and mobile APP to realize integrated operation of monitoring, control and scheduling

Functions of Smart Water System

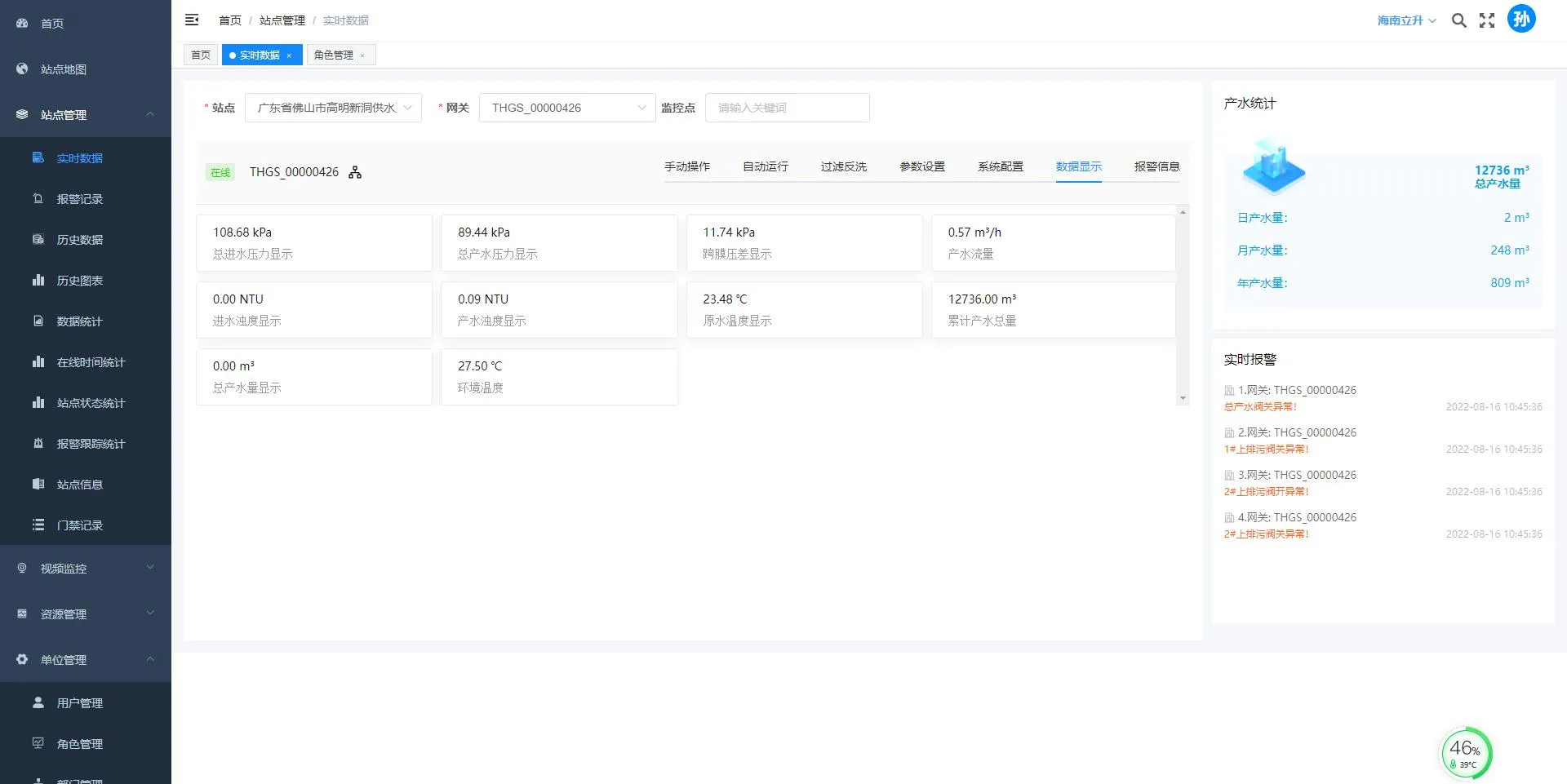

1. Full-process monitoring and early warning

• Real-time sensing: Covering water sources, water plants, pipeline nodes, and user terminals, it dynamically monitors water quality safety indicators (such as turbidity and microorganisms) and equipment health.

• Intelligent early warning: Configurable multi-level thresholds automatically trigger alerts via SMS, audio, and visual notifications when parameters exceed standards or equipment anomalies occur. Response time is ≤ 30 minutes.

• GIS visualization: Combined with electronic maps, it recreates monitoring point scenarios and supports manual and automatic inspections of water conservancy facilities.

2. Refined operations management

• Intelligent Scheduling: Optimizes pump operation based on water load forecasts, reducing energy consumption by over 15%.

• Leakage Control: Identifies leakage hotspots through pressure data analysis and clustering algorithms, reducing leakage rates to below 10%.

• Remote Control: Supports manual, automatic, and remote control modes for pumps, valves, and other equipment to adapt to different operating conditions.

3. Full lifecycle data management

• Automatically stores operational data and generates trend curves, supporting query, export, and traceability analysis.

• Builds equipment profiles to record installation time, maintenance history, and fault records for predictive maintenance.

• Utilizes SSL/TLS encrypted transmission and tiered authorized access to ensure data security (data integrity ≥ 99%).

Typical application scenarios

1. Improvement of rural water supply

In projects such as the ancient water plant in Dinghu District, Zhaoqing, Guangdong, the “small smart water plant + pipe network terminal monitoring” model addresses the problems of small water supply scale and dispersed users in remote areas, enabling direct drinking water access to villages and households, serving more than 5,000 villages and towns across China.

2. Industrial wastewater treatment

We provide water reuse solutions for eight major industries, including glass grinding and electroplating. For example, our Changsha glass grinding wastewater treatment project has a treatment capacity of 50,000 m³/d, saving over 30% of land compared to traditional processes.

3. Overseas water supply projects

Nearly 4,000 small and medium-sized water supply projects have been built in countries such as Japan and Australia, of which 3,300 projects in Japan have adapted to the complex water source conditions of islands through intelligent management.

(Water supply station at a ward office in Tokyo, Japan)

(A water plant in Australia)

(A water supply station in Cambodia)